- Main

- Solution

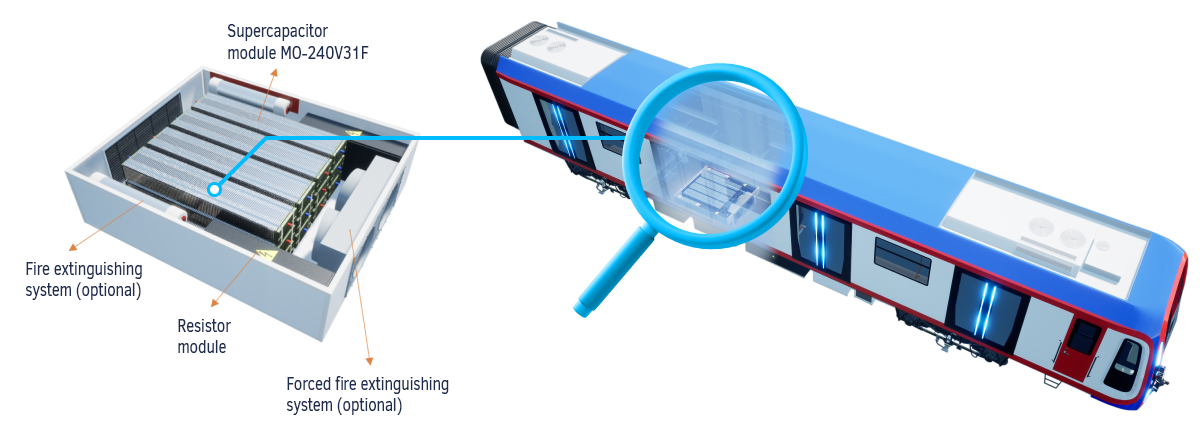

PRODUCT RANGE OF ENERGY WASTE COLLECTOR SYSTEMS FOR PASSENGER ELECTRIC TRANSPORT

- Monoblock with supercapacitor modules;

- Control system;

- Discharge module intended for maintenance;

- Fire-extinguishing system (optional);

- Forced ventilation (optional).

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

THE EWC PARAMETERS FOR A COMMUTER ELECTRIC TRAIN:

|

||||||||||||||||||||||||||||||||||

|

ENERGY REGENERATION SOLUTIONS FOR HOISTING EQUIPMENT

- direct connection to the DC bus of the crane frequency converter;

- connection to the trolley, which may feed several cranes..

|

|||||||||

|

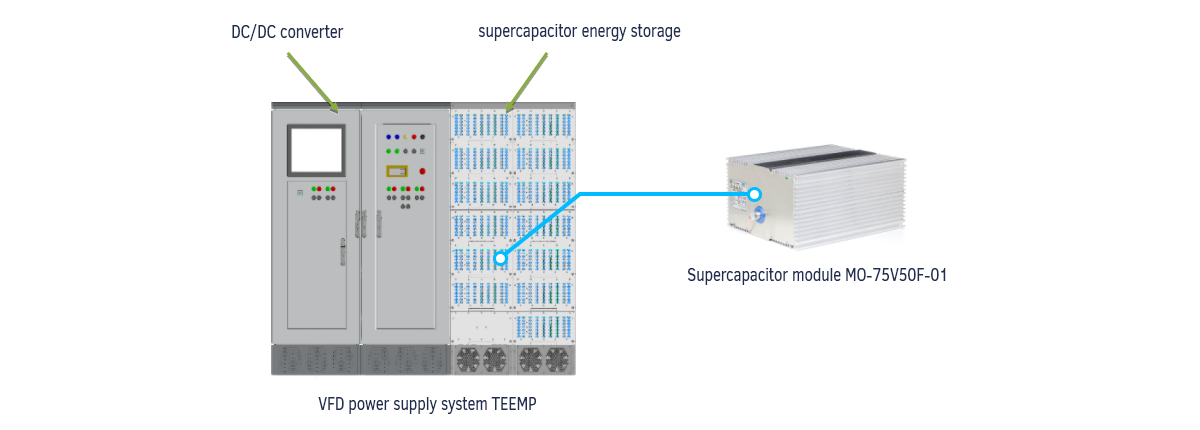

PROTECTION OF VARIABLE FREQUENCY DRIVES

Challenge

Disconnection of the variable frequency drive, including the actuators of the shut-off and control equipment, during voltage drops and a short-term, up to 10 seconds, loss of voltage in the network.

Solution

Power supply system of the variable frequency drive with an energy storage unit based on supercapacitors.

Connection is both feasible with a single variable frequency drive and a series of drives.

The system capacity and operating time are determined at the development stage of the terms of reference as required by the Customer.

Application:

- Equipment for sites of continuous process cycle;

- Equipment for supplying an enterprise with gas, water, heat, electricity (the shutoff and control fittings, compressors, pumps, boilers, etc.);

- Equipment that is sensitive to variable voltage and a short-term voltage loss.

TEEMP collaborates with the developers and manufacturers of power converters: NPK Morsvyazavtomatika, SNE LLC, Danfoss, Freqcon

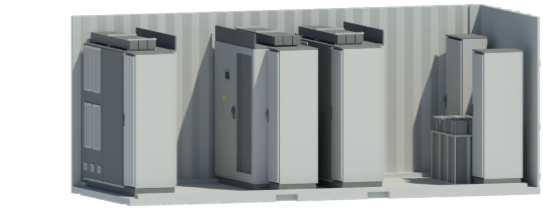

SYSTEMS FOR VOLTAGE DISTORTION COMPENSATION

System VDCS for variable frequency drives at oil refineries

The Voltage Distortion Compensation System (VDCS) is intended to protect the equipment against deep drops and interruptions in voltage, providing uninterrupted power supply to the infrastructure

Connection of the VDCS: in parallel to the existing automatic circuit breaker of the enterprise distribution substation.

| VDCS BASIC SPECS | |

| PARAMETER | VALUE |

| Rated power, kV*A | 30…1200 |

| Rated voltage, kV | 0,4 |

| Type of power supply | Supercapacitors |

| Duration of the compensated voltage drops: | |

| 100% deep, no less than | 2 |

| 50% deep | Unlimited |

| Optimal temperature inside container, °C | +25 |

| Seismic resistance under MSK64, points | 9 |

| VDCS FUNCTIONS | |

| CHARACTERISTIC | VALUE |

| Compensating a voltage drop up to 50% of the rated value | Unlimited |

| Compensating the input voltage loss in a phase or in full | 2 seconds |

| Increasing the time for autonomous operation | Scaling of the energy storage unit |

| Compensating the reactive power with the consumed load | up to 20% of the rated power |

| Correcting the output voltage during phase imbalance of the input voltage | available |

| Enabling direct startup of the asynchronous motor without disconnection of the VDCS from the network | Up to 5 rated power at VDCS |

SOLUTIONS FOR VOLTAGE DROP COMPENSATION

Voltage Drop Compensation Device (VDCD) by TEEMP is a parallel switching device with its own power supply.

Parallel switching makes it possible to operate in a reactive power supply mode and also simplifies the device installation.

The selected power supply is a storage subsystem based on ultracapacitors:

- High discharge current, which is required to eliminate problems caused by power drops and interruptions;

- Supercapacitors are much more reliable compared to lithium and lead-acid batteries, and are able to operate under frequent charge/discharge conditions;

- The supercapacitors characteristics are less degraded over time;

- Supercapacitors require lower operating costs.

VDCD basic specs

- Rated voltage: 6 kV

- Rated power: 1,200 kV*A

- VDCD rated energy capacity: 1.97 kW*h

- VDCD energy capacity at the end of the system lifetime: 1.33 kW*h

- Model of the supercapacitor modules: МО-162V-50F

- Quantity of the ultracapacitor modules: 24

- Climatic modification: NF1

- Lifetime: 10 years

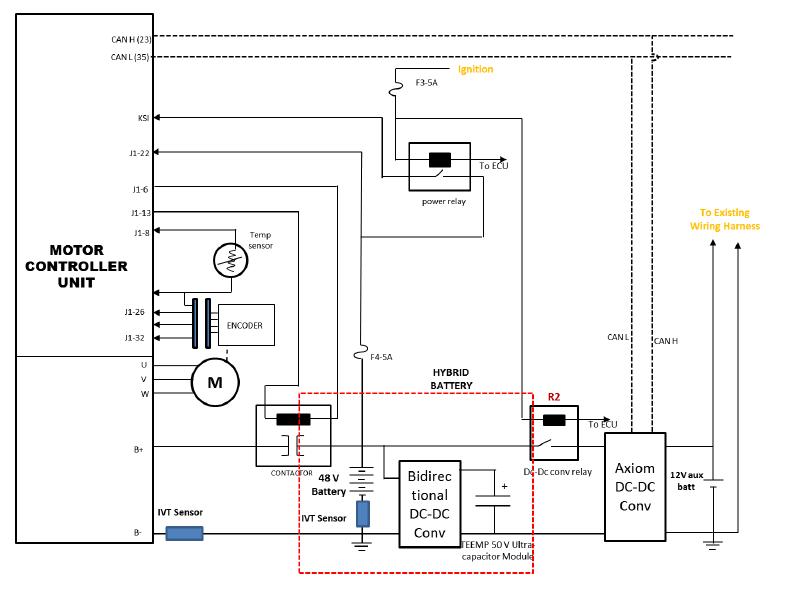

SOLUTIONS FOR HYBRID TRANSPORT

Belkommunmash city bus featuring TEEMP hybrid system

CONFIRMED FUEL EFFICIENCY OF THE HYBRID BUS – 27.7%

MORE EFFICIENT COMPARED TO A STANDARD BUS EQUIPPED WITH INTERNAL COMBUSTION ENGINE

The hybrid system consists of at least 2 power supplies. The first and main power supply is ICE, while the auxiliary power plant is a supercapacitor energy storage unit (ESU). The TEEMP storage unit is charged by the ICE and also by braking energy.

The main purpose of the supercapacitor ESU is to reduce fuel consumption by regenerating braking energy for further using it in acceleration mode.

| Parameters of the TEEMP module | МО-162V50F |

| Rated voltage, V | 162 |

| Maximum operating voltage, V | 162 |

| Capacity, F | 50 |

| Maximum operating current (300,000 cycles), А | 300 |

| Maximum pulse current, A | 750 |

| Short-circuit current, A | 10 000 |

| Energy capacity, kJ | 1 125 |

| Service life, charge/discharge cycles | 1 000 000 |

| Lifetime, minimum | 10 |

| Dimensions (LxBxH), mm | 1130x285x175 |

| Type of cooling system | Forced air-cooling |

| Protection class, IP | 65 |

| Quantity of modules in a system | 8 |

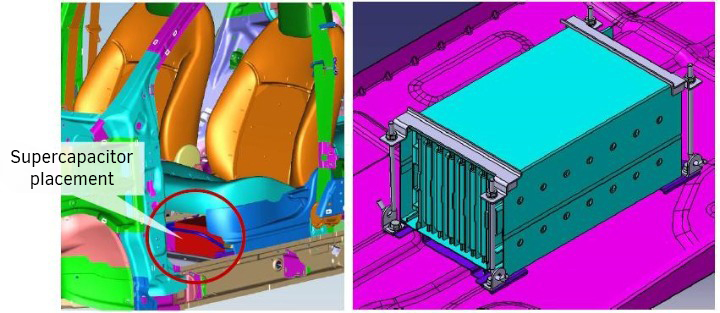

SUPERCAPACITORS FOR CARS WITH “MILD HYBRID”

ENGINE STARTUP SYSTEMS FOR HEAVY-DUTY VEHICLES

Onboard startup system CCO3-28V250F

Onboard startup system CC-12V200F

Mobile startup system CCC-28V250F

The main task – is to guarantee the startup of the internal combustion engine for wheeled vehicles with on-board voltage 12 V, 24 V.

Advantages:

- Operation in extreme climatic conditions: -60...+65 °C;

- Higher output currents (up to 1,500 A) providing a guaranteed cranking of the engine shaft;

- Useful life exceeding 10 years;

- Startup with 65% discharged storage battery;

- Extension of the standard battery lifetime by transferring the startup loads onto the TEEMP startup system;

- Reduction in the number of standard storage batteries;

- Reduction in weight and dimensions of the vehicle power supply system.